In industrial and commercial operations, compressed air is a critical resource, powering machinery, pneumatic tools, and processes. However, compressed air always contains moisture, which can cause corrosion, equipment damage, and product contamination. A Compressed Air Desiccant Dryer effectively removes moisture, ensuring clean, dry air suitable for sensitive applications.

This guide provides a comprehensive overview of compressed air desiccant dryers, including their operation, benefits, applications, and selection criteria.

What is a Compressed Air Desiccant Dryer?

A Compressed Air Desiccant Dryer uses moisture-absorbing materials, such as silica gel, activated alumina, or molecular sieves, to trap water vapor from compressed air. By passing air through a desiccant bed, the dryer achieves extremely low dew points—often as low as -40°F (-40°C)—making it ideal for processes that require ultra-dry air.

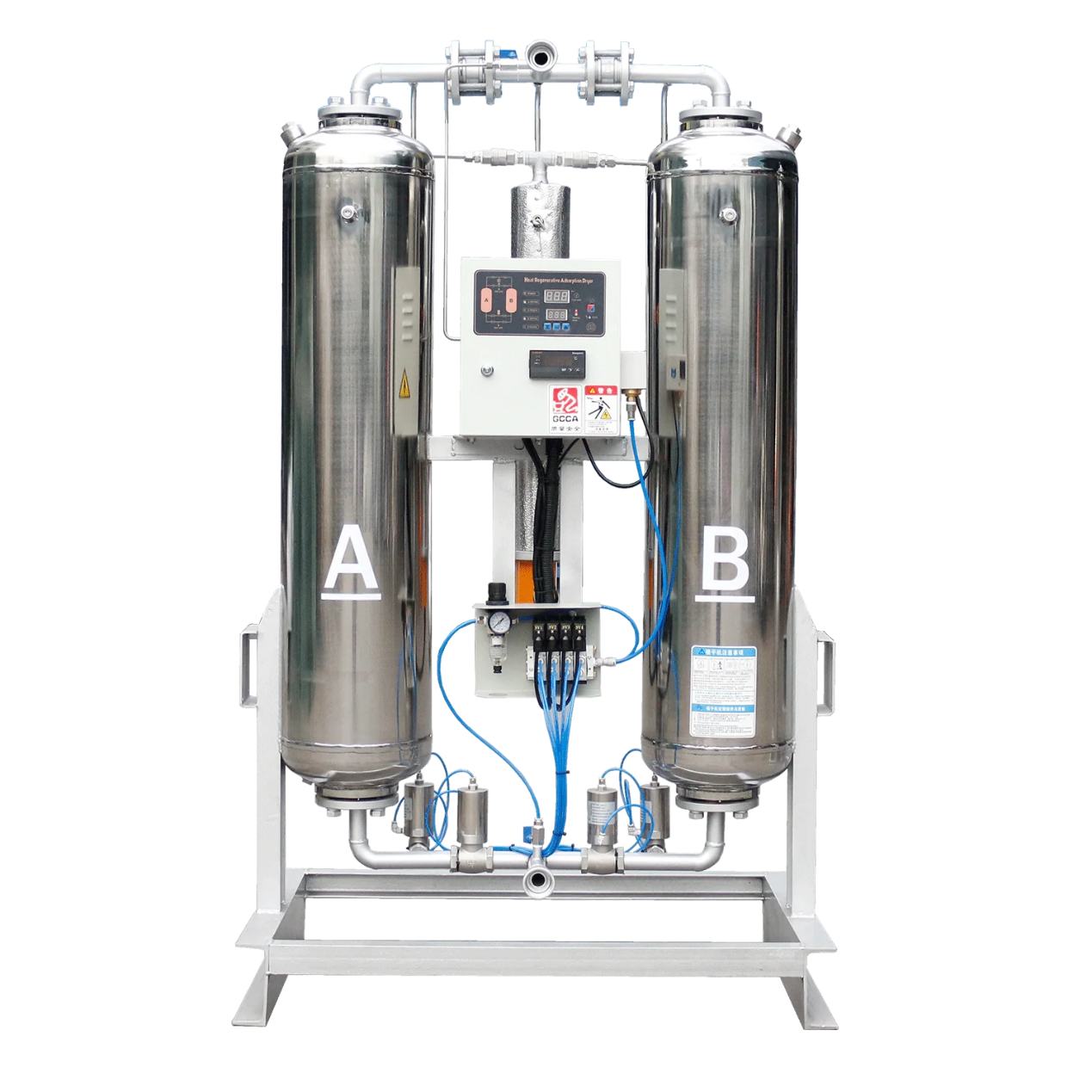

How Compressed Air Desiccant Dryers Work

The working principle of a compressed air desiccant dryer involves:

Compressed Air Inlet: Moist air enters from the compressor.

Desiccant Bed: Air passes through the desiccant material, where moisture is adsorbed.

Moisture Adsorption: Water vapor is trapped in the desiccant, drying the air effectively.

Dry Air Outlet: Dried air exits the system for use.

Regeneration Process: Saturated desiccant is regenerated through heat or dry air, allowing continuous operation.

This adsorption and regeneration cycle ensures consistently dry compressed air, even under demanding conditions.

Key Benefits of a Compressed Air Desiccant Dryer

A compressed air desiccant dryer provides multiple advantages:

Ultra-Low Dew Points: Supports sensitive industrial processes.

Continuous Moisture Removal: Reliable in fluctuating temperatures and humidity.

Equipment Protection: Prevents corrosion, rust, and contamination in tools and machinery.

Improved Air Quality: Meets stringent industrial air quality standards.

Energy Efficiency: Designed for efficient operation despite periodic regeneration.

Industries like pharmaceuticals, food processing, electronics, and chemical manufacturing rely on these advantages.

Industrial Applications of Compressed Air Desiccant Dryers

Compressed air desiccant dryers are widely used in industries requiring dry, contaminant-free air:

Pharmaceutical and Healthcare: Ensures sterile, dry air for tablet coating, packaging, and lab use.

Electronics and Semiconductor Manufacturing: Prevents moisture-induced defects in sensitive components.

Food and Beverage Industry: Maintains hygiene and prevents bacterial growth during production and packaging.

Automotive and Paint Industries: Provides moisture-free air for spray painting and coatings, ensuring superior finishes.

Industrial Manufacturing: Optimizes pneumatic tools and automation systems, reducing wear and downtime.

Selecting the Right Compressed Air Desiccant Dryer

Consider the following when choosing a compressed air desiccant dryer:

Air Flow Rate (CFM): Match the dryer’s capacity with your compressor’s output.

Dew Point Requirements: Select a dryer that meets your process dew point needs.

Regeneration Method: Choose between heat-regenerated or air-purged dryers.

System Size: Determine whether a single-unit or dual-tower configuration is appropriate.

Energy Efficiency: Look for features like cycling and reduced pressure drop to minimize energy use.

FAQ: Compressed Air Desiccant Dryers

How often should a desiccant dryer be serviced?

Every 6–12 months, including inspection of the desiccant bed, moisture separators, and filters.

Can a desiccant dryer handle all compressed air types?

Yes, particularly applications requiring ultra-dry air, such as pharmaceuticals, electronics, and food production.

How does regeneration work?

Desiccant is regenerated via heat or dry air to remove absorbed moisture, enabling continuous operation.

Can desiccant dryers achieve lower dew points than refrigerated dryers?

Yes, desiccant dryers can reach dew points as low as -40°F, while refrigerated dryers typically reach 35–40°F.

What is the typical lifespan of a desiccant dryer?

With proper maintenance, 10–15 years, with desiccant replacement every 2–5 years depending on usage.

Conclusion: Ensuring Reliable, Moisture-Free Compressed Air

A compressed air desiccant dryer is essential for industries that require extremely dry and clean compressed air. By efficiently removing moisture, it protects equipment, maintains product quality, and optimizes system performance. Selecting the right compressed air desiccant dryer ensures reliable operation, extended equipment life, and consistent, high-quality compressed air for any industrial application.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;