Mining sites are tough on everything—equipment, logistics, and supply chains included. Nitrogen is a critical utility in many mines, but relying on cylinders or delivered liquid nitrogen can be expensive, unpredictable, and operationally inconvenient—especially in remote locations.

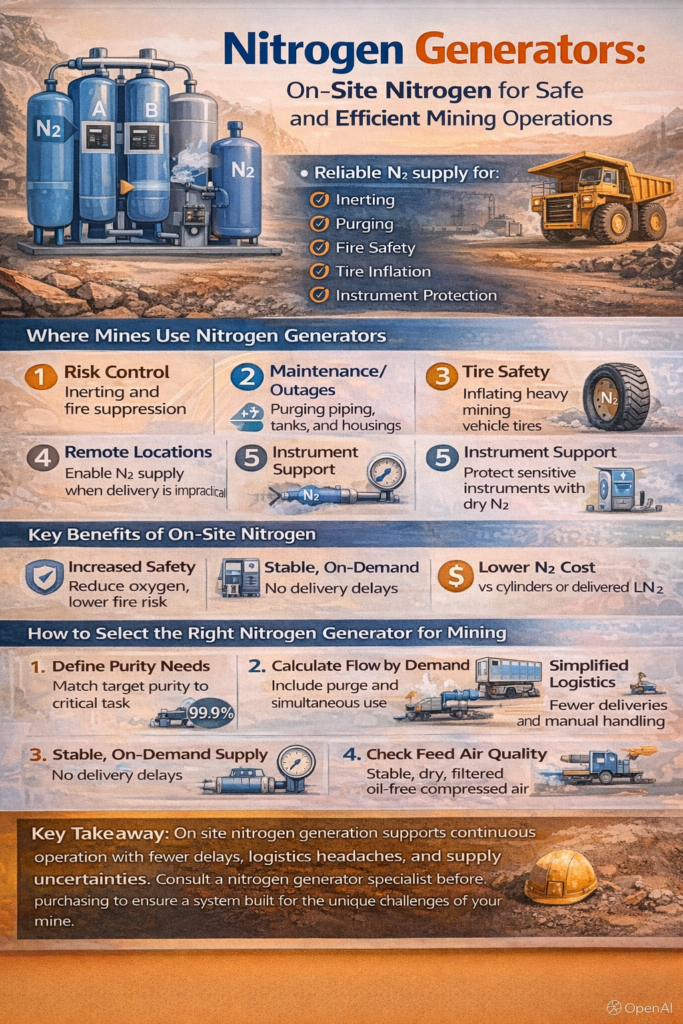

That’s why more operators are adopting an on-site nitrogen generator for mining. Whether you need nitrogen for inerting, fire risk management, purging, tire inflation, or instrument support, on-site generation can deliver a steady supply with fewer interruptions and lower long-term cost.

This guide explains where mines use nitrogen, the main generator options (PSA vs membrane), and how to select a system that matches real mining conditions.

Why Nitrogen Matters in Mining

Nitrogen (N₂) is inert, dry (when produced with proper air treatment), and widely used to:

Reduce oxygen concentration in enclosed spaces or equipment where oxidation or ignition risk must be controlled

Provide stable, clean gas for purging and protection of sensitive systems

Support operations in remote areas where deliveries are difficult or unreliable

In mining, the value is usually practical: keep production moving, reduce risk, and simplify logistics.

Where Mining Operations Use Nitrogen

1) Inerting and oxygen displacement (risk control)

Nitrogen is commonly used to reduce oxygen in specific applications where oxygen can increase risk—such as certain enclosed systems, sealed equipment volumes, or controlled process environments. This is often part of a broader site safety program and should always follow your mine’s engineering and safety standards.

2) Purging and line clearing (maintenance and reliability)

Nitrogen is widely used to purge and clear:

piping sections

tanks and vessels

filters and housings

gas lines used for process or maintenance support

Purging helps remove air, moisture, or residual vapors before start-up and after shutdown—improving reliability and reducing unplanned downtime.

3) Tire inflation for heavy mining vehicles

Large haul truck tires represent massive replacement cost. Nitrogen inflation can help reduce pressure variation caused by temperature swings, and it eliminates moisture that can contribute to internal corrosion of wheel components. Many sites standardize nitrogen for tire programs to improve consistency.

4) Fire prevention support (application-dependent)

Some mines use nitrogen as part of engineered fire prevention or suppression strategies in specific scenarios. The details vary widely by mine type, risk profile, and local regulation—so this should always be handled through qualified engineering design and site procedures.

5) Instrument and equipment support (where clean, dry gas is required)

Nitrogen can be used to protect or support certain instruments and equipment where moisture and oxygen are undesirable. (The exact purity and dryness requirements depend on the device and manufacturer guidance.)

On-Site Nitrogen vs Cylinders or Liquid Nitrogen: Why Mines Prefer Generators

Delivered supply challenges in mining

Mining sites often face:

long delivery lead times

transport constraints and weather disruptions

handling and storage complexity

safety exposure from frequent cylinder movement

price volatility (especially with remote delivery)

What an on-site nitrogen generator improves

Supply security

Generate nitrogen on demand instead of waiting for deliveries.

Lower total cost

After installation, operating cost is largely electricity + routine maintenance.

Operational consistency

Stable nitrogen pressure and flow for repeated processes.

Simplified logistics

Fewer deliveries and less manual handling.

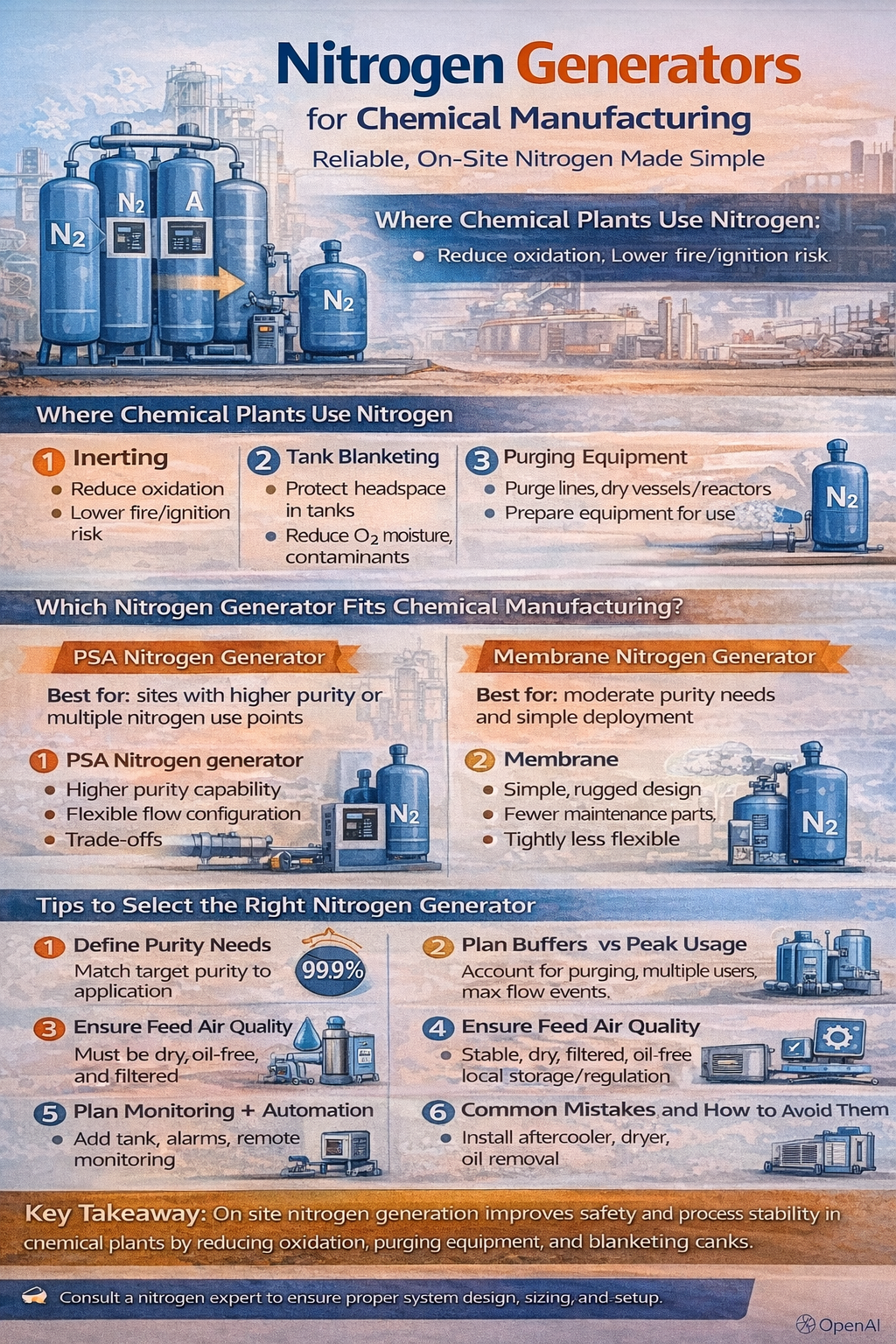

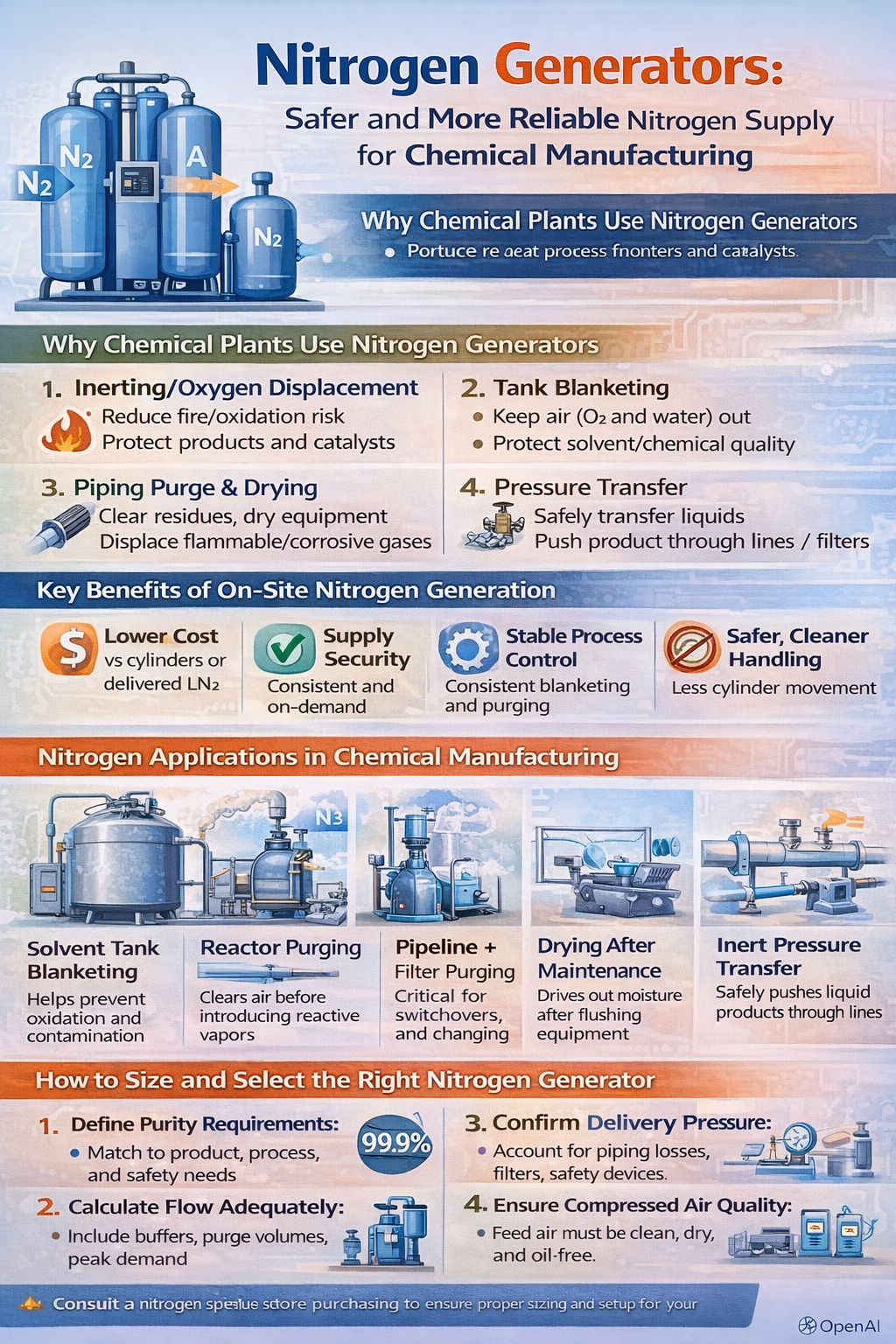

PSA vs Membrane Nitrogen Generators for Mining

Most on-site systems fall into two categories:

PSA Nitrogen Generator (Pressure Swing Adsorption)

Best for: sites needing higher purity or more flexibility

Common advantages

typically supports a wider range of purity targets (system-dependent)

good fit for mixed mine applications where requirements vary

strong cost-performance for steady demand

What to plan for

PSA relies on clean, well-treated compressed air

periodic valve and filtration maintenance is normal

Membrane Nitrogen Generator

Best for: rugged simplicity and moderate purity requirements

Common advantages

fewer moving parts, simple design

reliable in harsh environments with proper pre-filtration

fast response and compact footprint

Trade-offs

higher purity targets may reduce efficiency or increase air consumption

best when your nitrogen purity requirement is clearly within membrane’s economical range

Practical mining takeaway:

If your mine has multiple nitrogen use points or you expect growth, PSA often provides more flexibility. If you prioritize simplicity and ruggedness and your purity needs are moderate, membrane can be an excellent option.

How to Choose the Right Nitrogen Generator for Mining

1) Start with applications, not “purity numbers”

List every nitrogen use point:

inerting / risk control tasks

purging frequency and volume

tire inflation program scale

instrument or equipment needs

Then define which are continuous, intermittent, and peak demand.

2) Define purity based on the most demanding use

Different tasks can require very different nitrogen specifications. Many sites choose one generator specification that covers the most demanding case, then regulate flow/pressure per use point.

Tip: If only one area needs very high purity, it may be more economical to:

supply that point with a booster/polisher/backup source, or

design a dual-supply strategy

(rather than oversizing the entire plant for the highest spec).

3) Size for peak events (and use a buffer tank)

Mining operations often have spiky demand (large purges, simultaneous maintenance tasks, shift-based tire servicing). A nitrogen receiver/buffer tank can:

smooth demand spikes

stabilize outlet pressure

reduce the need to oversize the generator

4) Confirm delivery pressure where it’s actually used

Your generator discharge pressure must cover:

pipeline distance and elevation changes

pressure losses through filters/regulators

simultaneous use point draw

In large sites, distribution design matters as much as generator capacity.

5) Pay serious attention to feed air quality

A nitrogen generator depends on compressed air quality. For mining, prioritize:

effective water separation and drains

strong particulate filtration for dust

oil aerosol control (especially with lubricated compressors)

stable inlet temperature when possible

Poor feed air is one of the biggest causes of purity drift, valve wear, and unexpected maintenance.

6) Choose a mine-ready build

Look for practical features:

skid-mounted or containerized (easy deployment)

wide ambient temperature capability

corrosion protection / suitable coatings

simple access to filters and service items

remote monitoring for unmanned or lightly staffed areas

redundancy options if nitrogen is mission-critical

Common Mistakes Mines Make (and How to Avoid Them)

Mistake 1: Sizing only by average usage

Fix: include peak purge events, simultaneous users, and future expansion.

Mistake 2: Ignoring air treatment

Fix: design the compressor + aftercooler + separators + filters + dryer as one system.

Mistake 3: Overpaying for unnecessary purity

Fix: match purity to actual applications; avoid “max purity by default.”

Mistake 4: No buffer storage

Fix: add a nitrogen receiver tank to stabilize pressure and reduce generator cycling.

Bottom Line: A Nitrogen Generator Is a Mining Utility Upgrade

A well-designed nitrogen generator for mining improves more than cost. It improves uptime, consistency, and operational control—especially where deliveries are hard and conditions are harsh.

If you want, tell me these four numbers and I’ll outline a generator configuration and sizing logic tailored to your site:

Target nitrogen purity (or application list if unsure)

Required flow (average + peak)

Required delivery pressure at the farthest use point

Site environment (temperature range, altitude, dust level, available compressor air system)