Electronics and semiconductor products shape modern life—from smartphones and computers to smart appliances and industrial automation. Behind these devices, manufacturing processes such as lithography, etching, cleaning, and advanced assembly demand extremely tight control of oxygen, moisture, and contamination.

In many plants, one “invisible guardian” helps protect yield and reliability every day: the PSA (Pressure Swing Adsorption) nitrogen generator. By producing nitrogen on-site from compressed air, PSA systems provide a stable supply of inert gas to support critical steps across electronics and semiconductor production.

This article explains why nitrogen is essential, where it is used, and why PSA nitrogen generators are often the preferred solution.

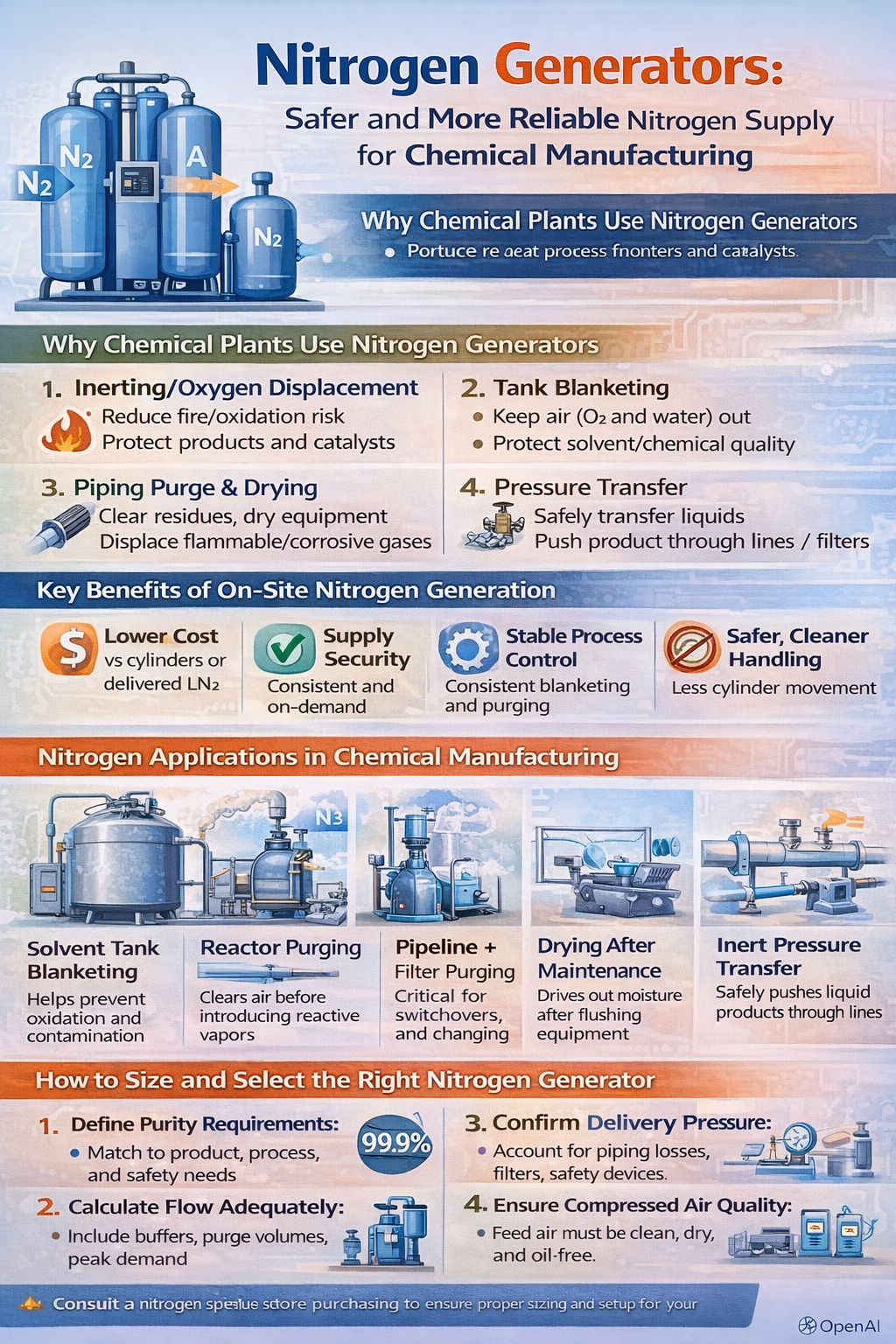

Why Electronics and Semiconductor Manufacturing Relies on Nitrogen

1) Creating a low-oxygen, clean environment to protect sensitive components

Even trace oxygen and contaminants can trigger oxidation or unwanted reactions that degrade performance and yield. Nitrogen is chemically inert and highly stable, making it ideal for inerting and oxygen displacement.

In semiconductor processes such as lithography and etching, nitrogen can help reduce surface oxidation and maintain a controlled atmosphere, supporting precision features and consistent outcomes—especially when combined with proper filtration and dry compressed air.

2) Improving soldering quality in SMT and electronics assembly

In PCB assembly, components are connected through soldering. At high temperature, solder and metal surfaces oxidize easily, which can reduce wetting performance and increase defects.

In nitrogen-inert reflow soldering and nitrogen wave soldering, nitrogen helps:

suppress solder oxidation,

improve wetting and wetting speed,

reduce solder balls,

lower bridging risk and other solder defects,

increase joint consistency and reliability.

The result is stronger electrical connections and more stable product quality.

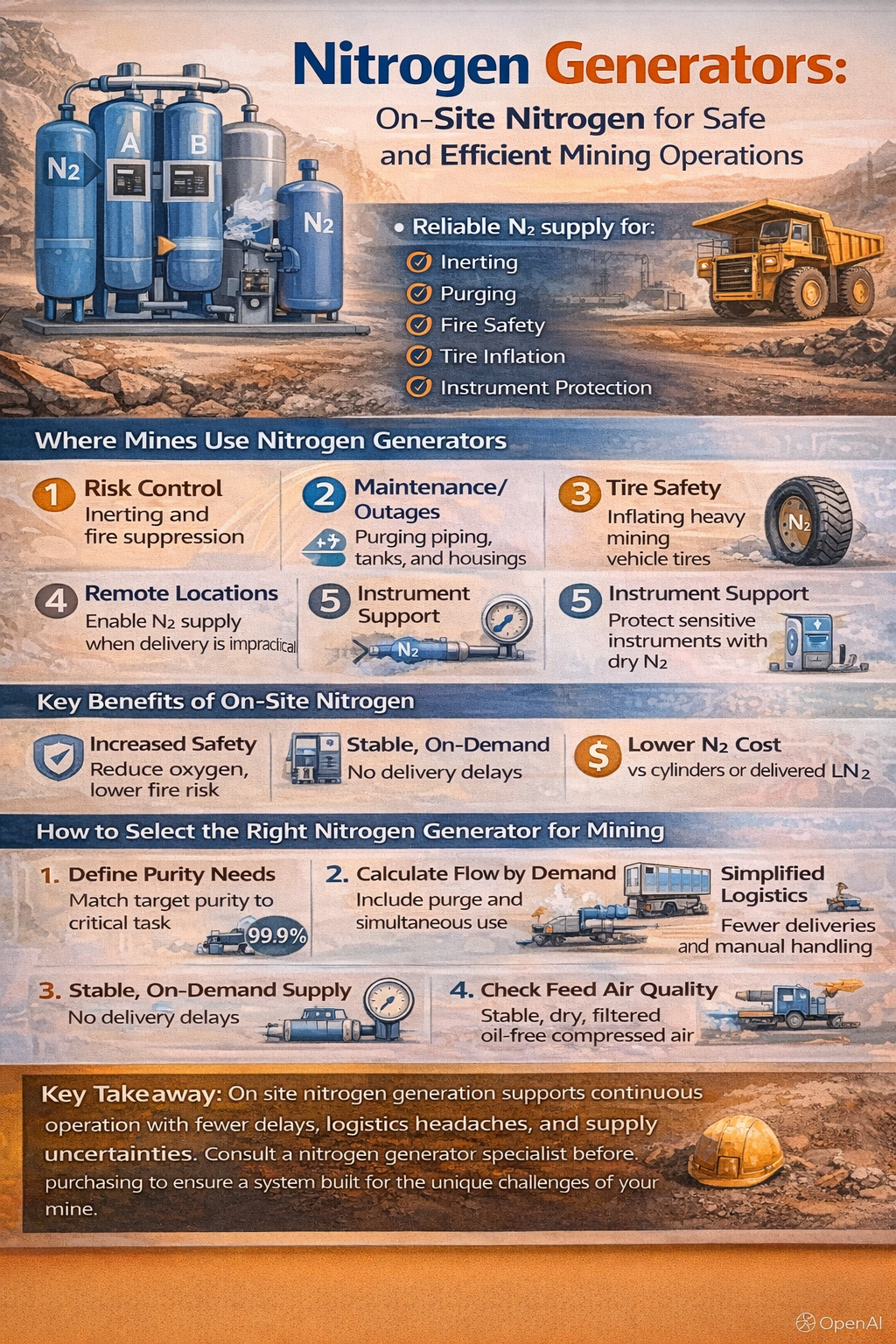

3) Gas transfer, dilution, and purging for safe and stable production

Nitrogen is widely used as:

a carrier gas to help move process gases through delivery systems,

a dilution gas to control concentration and stabilize process windows,

a purge gas to remove air (oxygen and moisture) before start-up and to clear residual gases after shutdown.

Purging and displacement using nitrogen can:

prevent process gases from reacting with air,

reduce safety risks when handling flammable, reactive, or corrosive gases,

protect equipment from corrosion caused by residual chemicals,

improve overall uptime and process repeatability.

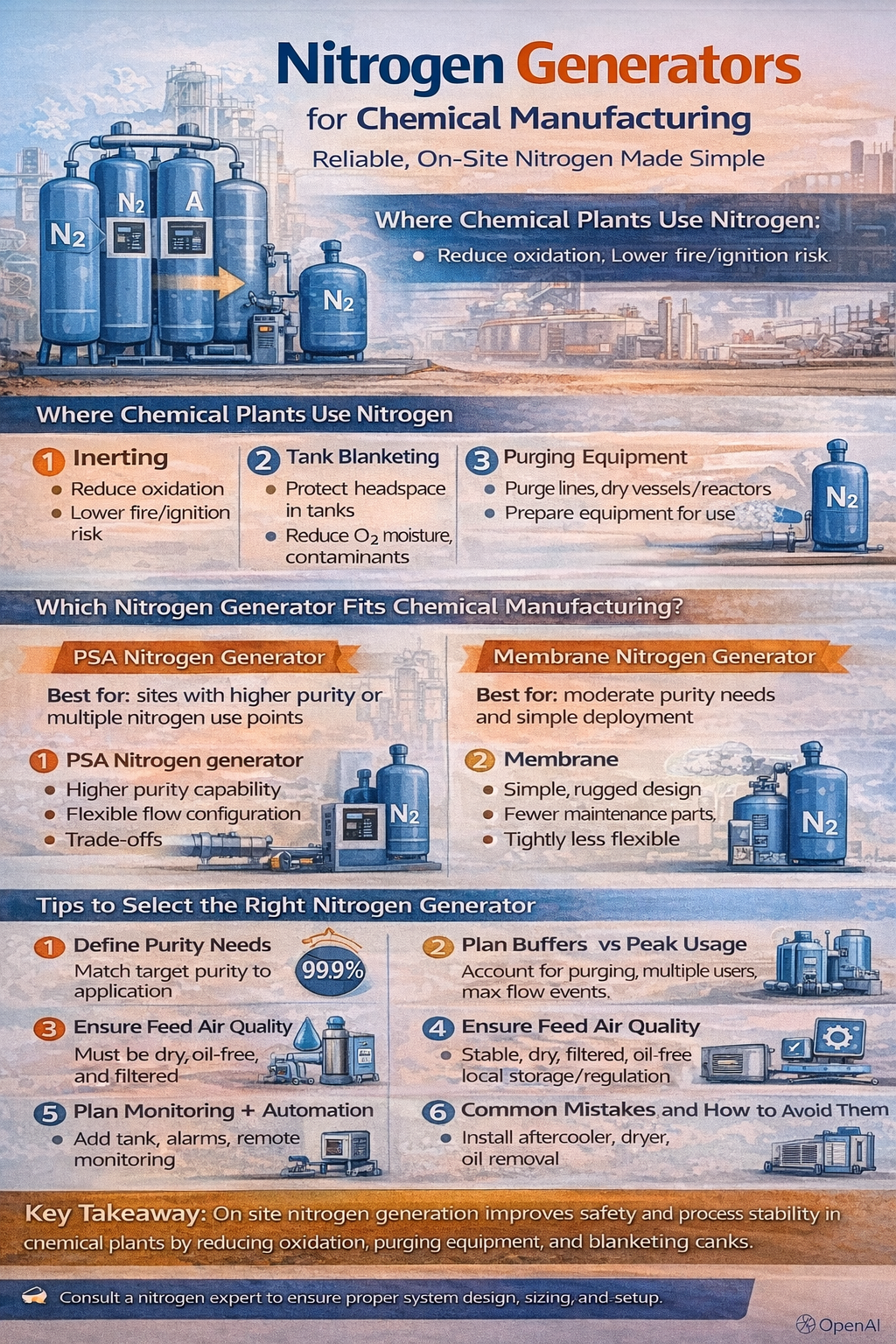

Why Choose a PSA Nitrogen Generator?

PSA nitrogen generation is a mature, widely adopted technology for on-site nitrogen supply. Compared with cylinders or liquid nitrogen delivery, PSA offers key advantages for many plants.

1) Fast, convenient on-site nitrogen production

PSA systems typically reach stable nitrogen production relatively quickly after start-up (time depends on capacity, purity target, and system design). With a compact, skid-mounted layout, installation is generally straightforward—often requiring only utility connections and commissioning.

Why this matters: electronics and semiconductor facilities value stable operation and predictable supply, especially where frequent cylinder handling or delivery logistics create constraints.

2) Lower operating cost and energy-efficient supply

PSA uses compressed air as the feed gas. The main energy cost is electricity for the air compressor and supporting components. For many users, PSA significantly reduces long-term nitrogen cost compared with bottled nitrogen or liquid nitrogen evaporation—especially when consumption is continuous.

3) Stable and reliable operation with automation

Modern PSA nitrogen generators typically support:

automatic operation via PLC control,

adjustable nitrogen flow, pressure, and purity (within design limits),

continuous monitoring of key parameters,

stable output for day-to-day production.

Low downtime and easy monitoring make PSA suitable for manufacturing environments that run long hours.

4) Flexible configuration and customization

Different users need different nitrogen specifications. PSA systems can be configured for various:

flow rates,

purity levels,

pressure requirements,

redundancy and buffer storage.

This makes PSA suitable for both smaller electronics workshops and large-scale semiconductor facilities, as long as the correct system architecture is selected.

Key Selection Factors (What Buyers Search for Most)

When choosing a PSA nitrogen generator for electronics or semiconductor manufacturing, focus on these practical parameters:

Required nitrogen purity

Different processes require different purity levels (for example, higher purity for critical inerting or sensitive steps, lower purity for general purging). Define the purity requirement by process, not by assumption.Flow rate and demand profile

Calculate average consumption plus peak demand. Consider whether usage is steady or fluctuating (e.g., soldering lines cycling).Delivery pressure

Confirm required pressure at the point of use and account for pressure losses across filters, dryers, piping, and regulators.Dew point and air quality upstream

PSA performance and stability depend heavily on feed air quality. Electronics and semiconductor applications commonly require:

reliable filtration,

oil control,

stable inlet temperature,

and often dry compressed air to support consistent adsorption behavior and protect downstream equipment.

Buffer tanks and redundancy strategy

Many plants use nitrogen buffer storage to smooth fluctuations and improve stability, especially for critical production lines.

What’s Next: Trends in Nitrogen Generation for High-Tech Manufacturing

As electronics and semiconductor industries push toward tighter process control and higher yield, nitrogen systems are also evolving. Key development directions include:

higher achievable purity for specialized needs,

reduced energy consumption through smarter controls and optimization,

improved monitoring, diagnostics, and integration with plant MES/SCADA systems,

more modular designs to scale capacity and simplify maintenance.

Conclusion

PSA nitrogen generators are widely used in electronics and semiconductor manufacturing because they help maintain controlled, low-oxygen environments, improve soldering quality, support safe purging and gas handling, and provide a stable on-site nitrogen supply with strong cost efficiency.

When selected and integrated correctly—matching purity, flow, pressure, and feed-air quality—a PSA nitrogen generator becomes a quiet but critical contributor to yield, reliability, and production stability.