Refrigerated Air Dryer: How It Works and Why It Matters

Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air

Lingyu’s advanced refrigerated air dryers are engineered to provide professional, energy-efficient, and reliable compressed air drying solutions for industrial applications.

By cooling compressed air and condensing water vapor, our refrigerated compressed air dryers effectively remove moisture and protect downstream equipment from corrosion, performance loss, and unexpected failures. With processing capacities of up to 15,900 CFM, our systems are designed to meet a wide range of industrial requirements, ensuring stable operation and enhanced productivity.

Explore our full range of refrigerated air dryers below and request a quote to find the right solution for your compressed air system.

Refrigerated air dryers are essential components in industrial compressed air systems, designed to remove moisture from compressed air before it reaches downstream equipment. Excess moisture in compressed air can cause corrosion, damage machinery, and reduce overall system efficiency.

Lingyu refrigerated compressed air dryers work by cooling the compressed air, condensing water vapor into liquid form, and removing it from the air stream. The result is clean, dry compressed air that protects equipment, improves reliability, and ensures consistent industrial performance.

Refrigerated air dryers play a critical role in maintaining air quality, operational efficiency, and system reliability across a wide range of industrial environments.

1. Corrosion Prevention: Moisture in compressed air is a leading cause of rust and corrosion in pipelines, valves, and pneumatic tools. Our refrigerated compressed air dryers effectively eliminate moisture, protecting critical components and extending equipment service life.

2. Enhanced Operational Efficiency: By delivering consistently dry compressed air, refrigerated air dryers help pneumatic tools and machinery operate at peak performance, reduce maintenance requirements, and minimize unplanned downtime.

3. Ensuring Product Integrity: In industries with strict quality standards—such as food processing, pharmaceuticals, and electronics—even small amounts of moisture can compromise product quality. Refrigerated air dryers ensure a stable supply of clean, dry air to safeguard products and processes.

4. Optimizing Energy Savings: Dry compressed air improves overall system efficiency. By preventing moisture-related losses, our refrigerated air dryers help reduce energy consumption while improving system stability and reliability.

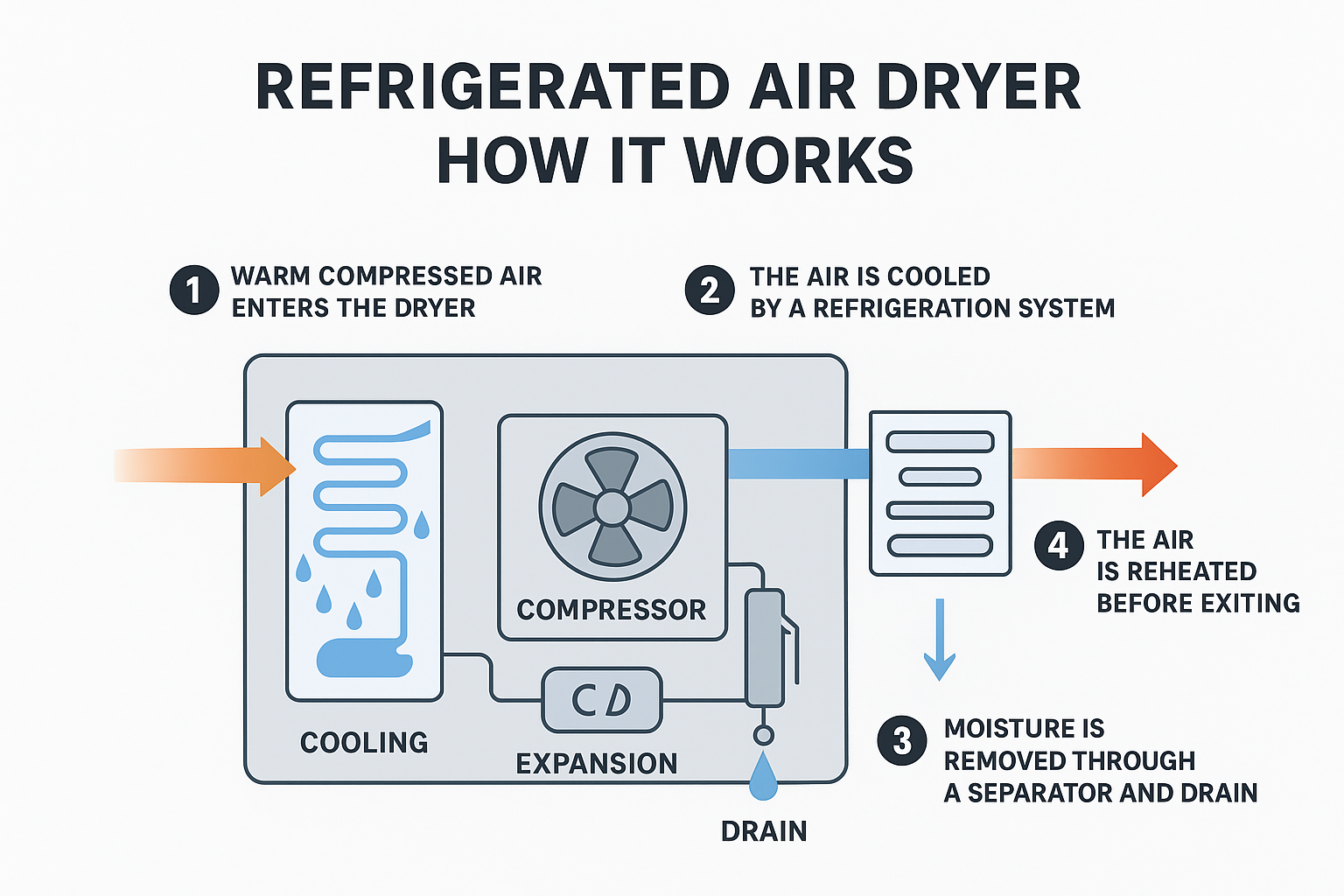

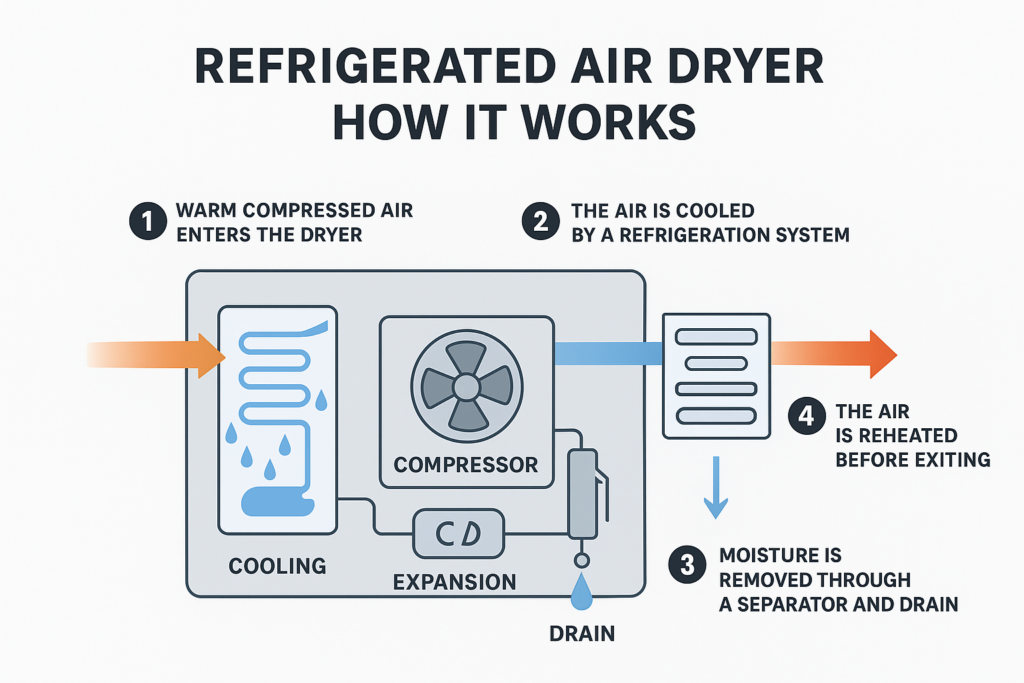

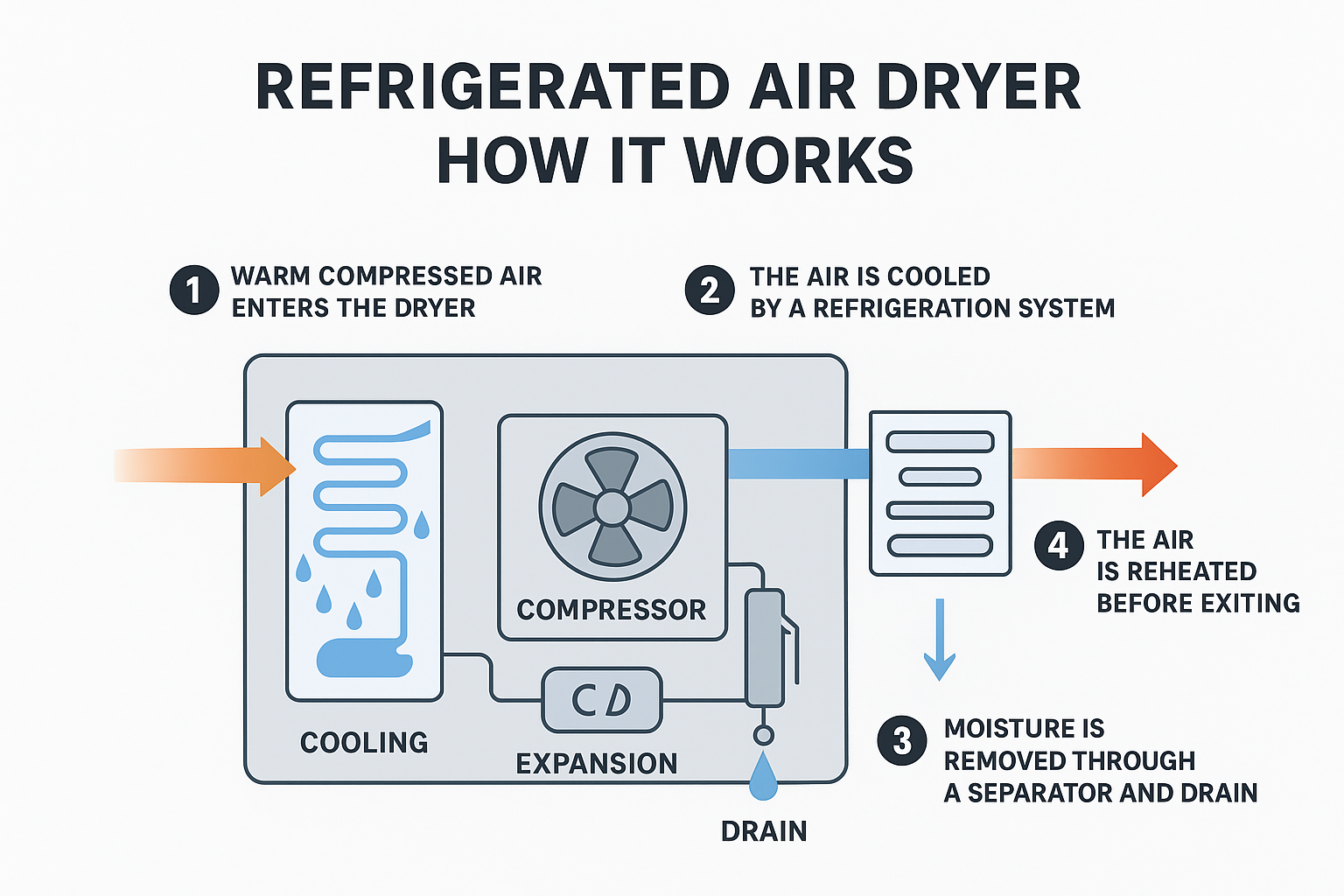

The working principle of a refrigerated air dryer is straightforward, yet highly effective. The drying process involves several key stages to ensure reliable moisture removal.

Process Overview:

Compressed Air Inlet

Hot, moisture-laden compressed air enters the refrigerated air dryer under pressure.

Cooling Stage

The refrigeration system cools the compressed air, lowering its temperature.

Condensation

As the air cools, water vapor condenses into liquid form.

Moisture Separation

Condensed water is separated from the air using an efficient separator and automatic drain.

Reheating & Discharge

The dried air is reheated slightly to prevent downstream condensation and then discharged into the compressed air system.

Lingyu offers two main types of refrigerated air dryers, each designed to meet specific operating conditions, installation environments, and cooling requirements.

Air-cooled refrigerated air dryers use ambient air as the cooling medium to remove heat from compressed air. Heat absorbed during the cooling process is released through an air-cooled condenser, allowing moisture to condense and be efficiently removed.

Air-cooled models are ideal for applications where water-cooling systems are unavailable or impractical. They are easy to install, cost-effective, and well-suited for most general industrial environments.

Water-cooled refrigerated air dryers use water as the cooling medium to dissipate heat from compressed air. Heat is transferred through a heat exchanger into a water circuit, which is typically cooled by a cooling tower or chiller system.

Water-cooled models are particularly suitable for high-capacity applications or environments with limited airflow. They offer stable performance, high efficiency, and consistent drying even under demanding operating conditions.

No.3, 2nd Street, yuanle Road, Dongsheng Town, Zhongshan City, Guangdong Province

(WeChat/WhatsApp):+8615756650906

№1:(WeChat/WhatsApp):+8618628146428

№2:(WeChat/WhatsApp):+8613823294942

Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air

In any compressed air system, moisture control is critical for maintaining performance, preventing corrosion, and extending equipment life. Without proper drying, condensation can lead to

A large refrigerated air dryer is an essential piece of equipment in many industrial compressed air systems. Designed to handle high air volumes, it removes

Selecting the right dryer is critical for maintaining clean, dry, and efficient compressed air. But how to size a refrigerated air dryer correctly is a